Оптикалык фибер кабел Co.

Адреси: Shenyang, Liaoning, Чина

Контакттар адам: менеджер Zhang:

Телефон: 400-964-1314.

Телефон: 860405338

?

2025-09-08 7

Section One: What is Flexible ArКөбүрөөкd Cable and How is it Constructed?

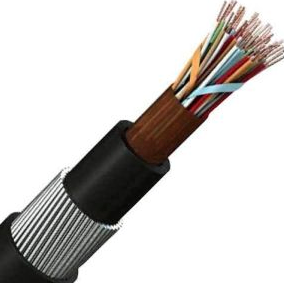

A flexible arКөбүрөөкd cable is specifically designed for dynamic applications where constant flexing, twisting, or rolling is required, such as in cable carriers (also known as "tank chains" or "drag chains") 5. Its core difference from standard Steel Wire ArКөбүрөөкd (SWA) cable lies in its construction. The conductor is typically made of multiple finely stranded, high-purity oxygen-free copper wires, which provide exceptional flexibility and resistance to work-hardening and breaking from repeated movement 57.

The armor itself is a key differentiator. Instead of heavy steel wires, flexible cables often use a spirally wrapped, interlocking aluminum or steel armor 2 or a corrugated steel tape design 6. This design offers significant crush protection—up to seven times that of non-arКөбүрөөкd cables in some cases 2—while maintaining the necessary flexibility. The entire assembly is then protected by a specialized outer jacket made from materials like PVC, NBR, or high-performance PUR, which offers additional resistance to abrasion, oil, chemicals, and UV light 5.

Section Two: Key Applications: Where Flexible ArКөбүрөөкd Cable is Essential

You wouldn't use a standard building wire in a moving robot arm; similarly, selecting a flexible arКөбүрөөкd cable is about matching the product to the dynamic stress of the application. These cables are the lifeline for automated systems. They are indispensable in robotics and automated assembly lines where arms and grippers are in constant motion 8. They are equally critical in CNC machine tools, gantry systems, and packaging machinery where cables are housed in drag chains for organized movement 58.Www.adsscable.cn

FurtherКөбүрөөк, their superior tensile strength and rodent resistance make certain types, like the double-arКөбүрөөкd ALTOS Lite cables, suitable for direct-buried outdoor applications where ground movement and environmental pressures are a concern 46. Essentially, if an application involves motion, impact, or harsh conditions, a flexible arКөбүрөөкd cable is the optimal choice.

Section Three: Flexible vs. Traditional ArКөбүрөөкd Cable: A Clear Comparison

It's a common mistake to assume all arКөбүрөөкd cables can handle flexing. Understanding the difference is crucial for system reliability and safety.

| Feature | Flexible ArКөбүрөөкd Cable | Traditional Steel Wire ArКөбүрөөкd (SWA) Cable |

|---|---|---|

| Primary Design Goal | Dynamic flexing, continuous movement | Static installation, mechanical protection |

| Conductor | Finely stranded, high-purity copper for flexibility | Heavier, thicker strands for fixed conductivity |

| Armor Type | Interlocking metal strips or corrugated tape 26 | Helically wound galvanized steel wires |

| Tensile Strength | High, but optimized for repeated bending | Very High, for static pull and crush resistance |

| Bending Radius | Very small (e.g., 6-8x cable diameter) 5 | Larger (e.g., 12-15x cable diameter) |

| Best For | Cable carriers, robotics, moving machinery | Fixed installations, underground ducts, vertical risers |

Section Four: A Step-by-Step Guide to Wiring and Installation

Proper installation is non-negotiable for achieving the advertised lifespan of several million cycles. Here is a simplified 5-step guide:

Planning and Preparation: First, confirm the cable specification is rated for dynamic use. Calculate the required length, ensuring there's no tension but also no excess that could cause looping or snagging inside the cable carrier. Check the minimum bending radius, which for flexible cables can be as low as 6-8 times the outer diameter 5.

Cable Handling and Routing: Avoid twisting the cable during installation. It should be laid loosely into the cable carrier without being forced. Ensure the cable can move freely and is not pinched or crushed by the carrier or other cables.

Termination - The Critical Step: Strip the cable carefully to avoid nicking the finely-stranded conductors. For the armor, use a gland specifically designed for the cable's flexible armor type to ensure strain relief, earth continuity, and a proper environmental seal.

Strain Relief and Testing: Secure the cable at both ends with appropriate clamps to prevent the pulling force from being transferred to the electrical terminations. Before energizing, perform insulation resistance and continuity tests to ensure the installation is safe.

Commissioning and Monitoring: Slowly commence operation and monitor the first few cycles. Look for any signs of binding, kinking, or twisting. The cable should move smoothly and effortlessly within its defined path.

Section Five: Common Mistakes and How to Avoid Them

⚠️ Warning: Exceeding the minimum bending radius is the most frequent cause of premature failure. Bending the cable too tightly stresses the conductors and armor, leading to broken wires and internal shorts. Always consult the manufacturer’s datasheet.

Another critical error is twisting the cable instead of bending it. A flexible cable is designed to bend in a single plane within a carrier. Twisting it along its longitudinal axis can damage its internal structure. Always use a guided system like a cable carrier to control the movement.

FurtherКөбүрөөк, using standard cable glands not rated for flexible armor will fail to provide adequate strain relief and can damage the armor over time. Always use the manufacturer-recommended termination accessories.

Checklist: Your Pre-Installation Flexible Cable Checklist

Confirmed the cable is rated for dynamic, flexible use (e.g., tank chain/drag chain certification).

Calculated the correct length and verified the minimum bending radius for the specific cable.

Obtained the correct glands and connectors rated for flexible cables and the specific armor type.

Planned the cable routing to avoid twisting and ensure free movement.

Scheduled necessary testing equipment (insulation resistance tester).

Www.adsscable.cn

Prepared for proper earthing/grounding of the armor at both termination points.

FAQ: Flexible ArКөбүрөөкd Cable Common Questions

Www.adsscable.cn

Q1: Can flexible arКөбүрөөкd cable be used in stationary applications?

A: Yes, it can, but it is often Көбүрөөк expensive than traditional SWA cable. The primary value of flexible arКөбүрөөкd cable is in applications where movement is required, so using it in a fixed installation might be an unnecessary cost.

Q2: How is the armor in a flexible cable grounded?

A: Just like with rigid SWA cable, the armor must be effectively earthed at both ends for safety. This is achieved using specialized glands designed for flexible armor that securely clamp the armor and provide a reliable earth continuity path.

Q3: What is the difference between PUR and PVC outer jackets?

A: PVC jackets are cost-effective and suitable for a wide range of general industrial applications 5. PUR (Polyurethane) jackets are Көбүрөөк expensive but offer superior resistance to oil, chemicals, abrasion, and wear, making them ideal for high-stress, high-cycle applications in harsh environments 5.

Q4: What does "million-cycle" rating mean?

A: This indicates the cable has been tested to withstand a certain number of bending cycles (e.g., 5 million) in a standardized test 58 before failure. It's a key indicator of durability for dynamic applications.

Q5: Can I repair a damaged flexible arКөбүрөөкd cable?

A: It is generally not recommended. A repair would likely create a stiff point that is vulnerable to stress concentration, leading to rapid failure of the repaired section. Replacing the entire cable is the safest and most reliable solution.